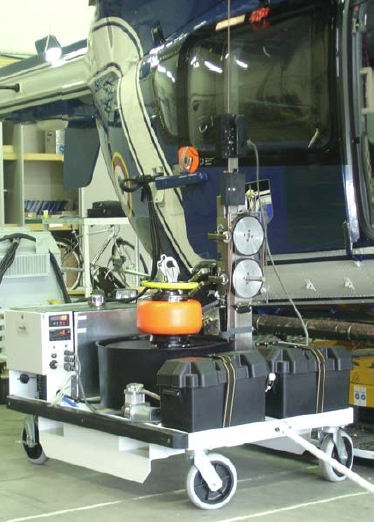

Rescue Hoist Ground Support Equipment

Air Affairs Australia are the sales and service centre

representatives for Zephyr International Rescue Hoist Ground Support

Equipment for Australia and New Zealand.

The current practice for tensioning and load checking the wire rope on the rescue hoist is to use a 600 lb load hanging off a helicopter. It is a very expensive practice and sometimes it can shock load the wire rope, thus requiring replacement. Helicopter rescue hoists use tension rollers to keep their wire rope cable tight on the drum. The tensioning device relies on physical contact with the wire rope and tend to milk the wire rope’s inherent looseness to the lower end of the rope. Thus the wire rope starts to unwind resulting in loose outer strands. As a preventative measure, the hoist manufacturers recommend applying a high load while retracting the wire rope after running it out for an inspection or a wash down after every mission. Zephyr's ground support equipment will meet this requirement.

Historically hoist failures occur when the hoist is run under no load and the wire rope gets loose on the drum and fouls the entire mechanism. Since the tensioning systems that are in use today only provide approximately 7 to 20 lbs of force on the wire rope, the cable tensioning system can easily be overcome and the wire rope loosens up on the drum. This normally will not happen in flight but happens with regularity when the hoist is operated on the ground during inspections, maintenance etc. When a hoist wire rope loosens and fouls the hoist. The damage that results can cost thousands of dollars to repair and significant time with the OEM. In addition if the wire rope mis-wraps on the lower layers when winding and the operator does not see the mis-wrap the wire rope can foul in flight putting the crew and the mission in jeopardy.

Features of the Zephyr unit are:

- Can be used on all types and brands of rescue hoists.

- Portable to and from the helicopter in order to perform pre and post flight checks of the wire rope and rescue hoist system.

- Maintains positive manual tension on the wire rope as it extends and applies a heavy load over the length as it retracts, while protecting the wire rope in a rotating tub during hoist maintenance.

- Apply's a heavy load over the entire length of wire rope on the hoist drum as it retracts the wire rope while the aircraft is on the ground.

- Allows the wire rope to relieve its inherent twist as it winds on and off the hoist drum. This is to simulate as closely as possible the effect of running the wire rope in and out in flight under load.

- Keeps the wire rope off the ground and in a protective enclosure during hoist maintenance.

- Clean and dries the wire rope during post flight inspections after salt water use.

- Lubricates the wire rope if required by the manufacturer.

- Allows one person to perform all inspections and maintenance operations in a minimum amount of time.

- Allows the inspections to be performed with the hook and bearing attached to the wire rope.

- Measures and provides a record of the wire ropes physical condition over its installed life.

- Helps install new wire ropes and condition them.

For more information visit the Zephyr International website - www.zephyrintl.com